⚙️ Master the art of perfect spheres with precision and speed!

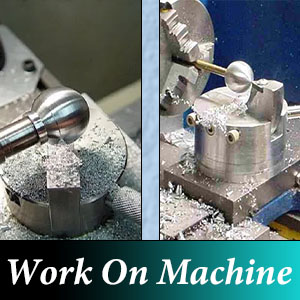

The ASSORTS Lathe Ball Turning Attachment is a precision metalworking tool designed for Myford and similar lathes. Featuring a dual-bit holder, engraved radius scale in metric and imperial units, and a smooth ball-bearing base, it enables accurate turning of convex and concave metal spheres. Constructed from hardened alloy steel, it offers durability and vibration-free operation for professional and hobbyist machinists alike.

| Brand | ASSORTS |

| Material | ALLOY TOOL STEEL |

| Item dimensions L x W x H | 6.3 x 5.12 x 4.33 inches |

| Item Weight | 3.3 Pounds |

| Specification Met | ABEC 1 |

| Bearing Type | Ball Bearing |

| Compatible Lubricant | Grease |

| Outside Diameter | 42 Millimeters |

| Manufacturer | Assort Machine Tools Co. |

| Part Number | BT-O-S |

| Item Weight | 3.26 pounds |

| Product Dimensions | 6.3 x 5.12 x 4.33 inches |

| Item model number | AST01 |

| Is Discontinued By Manufacturer | No |

| Size | Round Base with Size Scale – Double Bit |

| Item Package Quantity | 1 |

| Batteries Included? | No |

| Batteries Required? | No |

K**.

Maximum of 1-5/8" diameter of your work piece!

Works great for aluminum! Haven't tried stainless yet? That will be the real test!

M**G

Be prepared to modify this thing to fit your lathe

Takes a little modification for it to work flawlessly, but it’s worth it

U**C

it is what it is, functional but only marginally

Haven't used it yet as I need to make a raiser for it to fit my lathe ( Emco V10P) BUT initial impression is as expected, cheaply made, needs finishing ( deburring, loctiting screws etc) as another reviewer stated it should have a bearing on the pivot as I can see it will be a high wear point if used anything more than rarely but it should do the minimal work I'm planning on. Needs a scale on side for referencing radius it is cutting to at least get you in the ball park of what your trying for

R**H

Don’t be afraid of this. Works great.

5stars from a non machinist. I adapted this to use on a 9 in. South Bend lathe. Worked perfectly. Got an acceptable finish on my piece. No sanding or filing only wire wheel to shine it up.

B**N

Pos , needs a lot of modifications to work.

This is a joke, there is no fine adjustment on the tool block and it rides in a square groove not a dovetail.

D**Y

shipped without handle

shipped without handle and there's a gap on the bearing assembly that will lock up the rotating mechanism if you try and tighten the screw all the way i had to make a bushing to keep the screw from locking it up and be able to be tight enough to not loosen on its own

A**R

The quality.

Was not able to use it on my lathe,but it's a well designed tool,

T**N

which doesn't give a great finish. A little tricky to set the diameter ...

Works ok,, but bearing could be improved to make it have less play... Still just a little loose, which doesn't give a great finish. A little tricky to set the diameter of the cut (manual measure).I had to make a custom fixture for my lathe, but it worked out ok..

TrustPilot

1 个月前

1 个月前