⚡ Unlock your maker potential with the ultimate beginner CNC powerhouse!

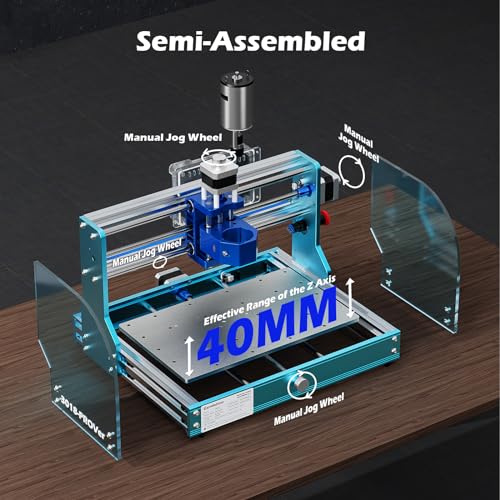

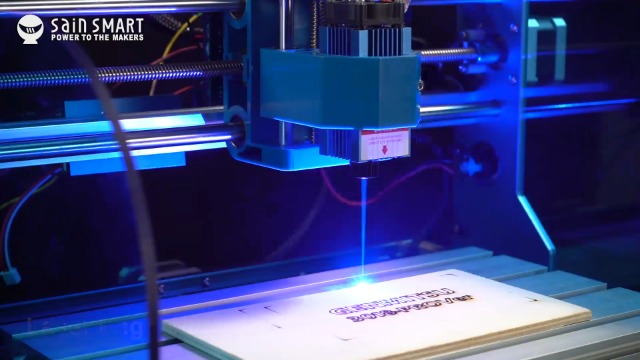

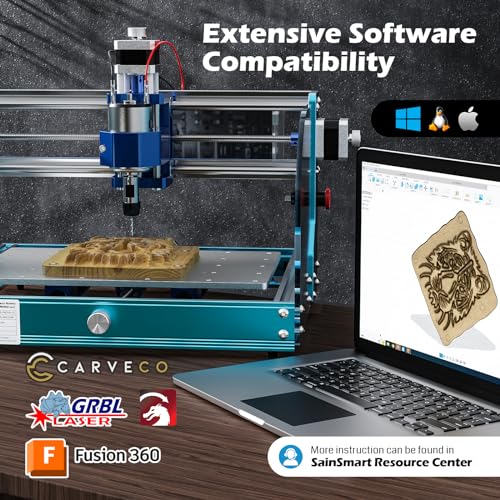

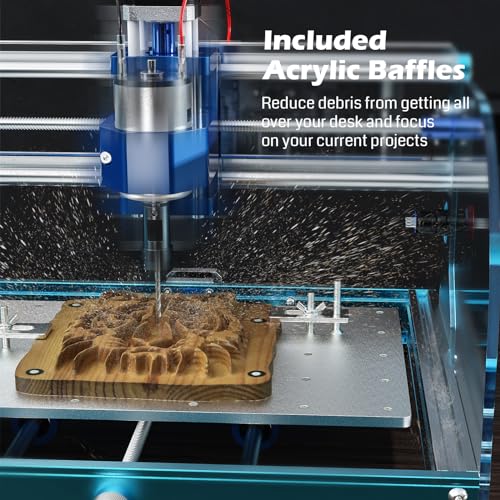

The SainSmart Genmitsu 3018-PROVer V2 is a beginner-friendly CNC router featuring a 10,000 RPM spindle, a compact 16.5" x 11.4" footprint, and pre-assembled components for quick setup. Designed for versatile engraving on wood, acrylic, plastics, and soft metals, it includes safety limit switches and an emergency stop. Perfect for hobbyists and small business creators, it supports a wide range of CAD/CAM software and offers upgrade paths to expand functionality.

| ASIN | B07ZFD6SKP |

| Amperage | 1.03 Amps |

| Base Type | Fixed |

| Batteries Included? | No |

| Batteries Required? | No |

| Battery Description | Corded electric |

| Best Sellers Rank | #148,034 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #10 in Power Milling Machines |

| Brand | SainSmart |

| Customer Reviews | 4.2 4.2 out of 5 stars (1,274) |

| Date First Available | October 21, 2019 |

| Description Pile | Corded electric |

| Horsepower | 96 |

| Included Components | CNC Router Machine |

| Item Package Quantity | 1 |

| Item Weight | 20.3 pounds |

| Item model number | 3018-PROVer V2 |

| Manufacturer | SainSmart |

| Material | Aluminum |

| Maximum Rotational Speed | 10000 RPM |

| Part Number | 3018-PROVer |

| Power Source | Corded Electric |

| Product Dimensions | 16.54"W x 11.42"H |

| Style | 3018-PROVer |

| UPC | 816550022917 |

| Voltage | 24 Volts |

M**.

This is a great machine. Prepare for an education.

Cutting to the chase, this machine is great. It's built like a tank, assembly instructions were fine, and there are a ton of resourced available online. I got my machine on Sunday, and on the following Saturday was able to cut the piece in my attached picture with no issues. In fact, the only issues that any of my cuts have had were of my own making. The machine works very well. That said, prepare to do some learning, some troubleshooting, and some problem solving. This is my first CNC, but I have extensive experience with 3D printers, and they're the same way. This machine isn't there to hold your hand while carving out intricate masterpieces. It's a tool that you need to learn to use. Another reviewer said something like "8 hours of failure was too much." (I had the same problem that he did. It was solved by changing the "Safe Retracts" setting in Fusion360.) If 8 hours of failure is too much for you, then this isn't the machine you want. To make this (or really any CNC machine) "work", you will need some basic understanding of G Code, 3D modelling, woodworking, and electronics. You don't need to be a master at any of this stuff, but you're going to touch all of it. It will take time. You will screw things up. You will get sawdust in your hair. That's what makes these things fun. Now, more specific to this machine itself, I was very, very impressed. There are many very similar units on Amazon, and I selected this one because of the included upgrades, and the known brand name. I found the machine to be extremely well built, and straightforward to assemble. The inclusion of limit switches is important. While limit switches can be a bit frustrating, they are there to make sure you don't accidentally send the machine a command that will damage it, and the work perfectly for that. I find the offline controller to be wonderful. There seems to be a lot of hate for this part, but I like that I can run he machine "headless" and not have to leave a laptop in my dust shop. I actually had a much smoother experience using the offline controller than I did using the PC-based Candle, but they both do the same job. My motor doesn't wobble, isn't loud, and hasn't had any issue cutting through various woods at 300mm/min. I did several calibration tests on the machine as soon as I got it built, and didn't have to adjust anything. The only bad things about the machine are the hold-down clamps that are included (they work, but are the definition of "fiddly"), the included Vee bits (again, they work as they should, but why give me a bunch of Vee bits and no end mill?) and the size of the workspace. The 3018 is actually a great size for a small workspace like mine, where it will need to be moved and worked around, but just like everyone else, I'd love to be able to make bigger stuff. I've probably said enough glowing stuff about this device, but I'll sum it up, here. When I spend ~$350 on a piece of Chinese technology that's based on open source designs, I expect to get a pretty low-end product that I can usually upgrade to make it useful. In this case, I got a solid, well-deigned, functioning piece of gear. I haven't been this amazed at how well a cheap gadget works since the Elegoo Mars Pro. If you're looking for a cool tool with a steep, but fun learning curve, look no further. If you want to easily and quickly cut wood (or metal) parts with the push of a button, maybe wait a few years. Software That I Used: -Candle (included) for machine control -Easel (very limited free use) for design and GCode Creation -F Engrave (free) for GCode creation -Carbide Create (free) for design and GCode Creation -Fusion360* (free) for design and GCode creation -Inkscape (free) for image design *Fusion360 is the real workhorse, here. It has by far the most features, but also the steepest learning curve. If you're familiar with Fusion360, you'll have no trouble. Otherwise start with Carbide Create.

A**J

Perfect Starter CNC Machine

Small but solid CNC machine. This was the perfect machine to learn how to use a CNC machine. It's not powerful, but it makes very accurate cuts. As a hobbly machine, I have managed to make projects that were up to 10-1/4" x 12" x 3/4".

R**O

Good kit but software iffy

The machine kit builds OK. Web videos are much better than the manual for assembly because you see it at angles. Lots of small parts but accurate in pre-drilled holes etc. The operation is not for beginners even though the machine is aimed at beginners. The attached controller is not intuitive at all and hard to use at best. When it works it does work. Get Dremel etc routing bits (you will need to cut it down in length.) The supplied bits are more for engraving than anything else, like cutting plastic, wood etc. The machine is solid. The software like Easel is odd to use, and Candle works but is also odd. An "end" stop error requires a reset which itself requires a sequence of frustrating button presses. The optional waste boards work but the hold down clamps are not usable to their full degree. It is fascinating overall, so I would recommend it, but go in expecting some setbacks.

P**L

Great for small projects. I recommend Easel Pro software.

Very happy. Strongly suggest using “Easel Pro” software. If you are a novice at CNC, you will need to be patient. If you’re familiar with CNC, you’ll enjoy its accuracy and ease of use. If you’re breaking bits, you’re being too aggressive with the cuts. Be patient and use common sense. Enjoy!! Peace!

A**R

Product was damaged, support contacted updates to follow

Although I have not had a chance to use the product yet my initial review will be on it's unpacking, setup and condition on arrival. Was packed securely and when it was received the box was undamaged. Lots of stuff neatly packed in the box. Installation manual was clear with some included videos on the thumb drive. Setup will take awhile but just follow the directions and work carefully and you will have no issues. Everything looked great and went together seamlessly. I stared to set the Z Probe and as the Spindle moved over to the home position and I started to set the Z probe Kit onto the table I noticed a big ding on the top left corner of the table, see the attached pics. Further inspection of the top shows some scratches and scuffs in other areas too. During installation I used the thin flat Styrofoam packing to put the top of the table on to prevent such scratches so I'm 100% sure this is not user induced. Things like this happen and although unfortunate and time consuming (replacements) it's just part of the deal if you are the unlucky one. I don't feel that a used machine was shipped to me but looking at the top and the scuffs and this damage on the corner, it was probably damaged during installation or packing. Either way, I have contacted the seller and requested a replacement bed. I'm ok with that as long as I get a new bed back. I have left a 3 rating for the time being once I get the sellers response and actions I will report back here. Anything less than a "Sorry sir we will get one out to you right away will not bode well". Not asking for a full machine, I'm ok with a replacement bed as long as it's a "New" one. Stay tuned! UPDATE: 17 Jan 2021, So the seller contacted me right away and sent me a bed from China. It was on backorder and is enroute. Unfortunately I had issues with the machine. There is a Z Probe Calibration so each time you place a piece of work on the bed you calibrate the Z Axis with the probe so the machine knows where the surface of your material is. This worked once after that can't get it to work. Sometimes commands are not executed from the machine just when jogging with Candle the software that comes with it. Thought maybe it was a COMMS issue so I tried the offline controller. Same problems. I emailed the company many times, but took forever to get a response, I thought I had fixed the issues by uninstalling the driver and re-installing but eventually the Z Probe Calibration stopped working again. You can calibrate the Z Axis without the probe but why? If it's there I want to use it. Boxed it up and it's on the way back with a new unit to arrive Tuesday. BTW you can't disassemble the machine in 15 minutes let alone assemble it so this is a marketing gimmick about 15 minute install. If you assemble them daily yes you can but as a new buyer you will want to read through the manual and take your time. Think 45-90 minutes to assemble especially if your first CNC. Update 28 Jan, 21. Little bit of a delay in my update but I did receive a new unit. I returned the previous one through Amazon and a new CNC arrived a few days later. This one shipped from a different location. This router appeared to be brand new. Assembled it and everything tested and ran perfectly. I did order a bed extension kit and you guessed it, received it damaged and used. In the process of getting that replaced. So in conclusion, as far as operation, well all I've done for the last 2 weeks is deal with replacing used items purchased as new so really haven't had time to use it. I did mill the top of my spoil board to make sure it's flat. As far as dealing with the company, be warned you have a high probability of receiving used items when you purchase new. Look them over carefully. Not sure if this is Amazon or Sainsmart. If it's Amazon, it's easy to return and just inconvenient. If you purchase anything through Sainsmart, not so convenient and it takes a while but they did replace the bed and the bed extension so I have to give them credit there. I'll leave this at 3 stars due to the headache of multiple returns. EDIT: 8 Feb 2021. So I will make my final review here. I did receive a new unit which works great. I had also ordered a Y Axis bed extension from Sainsmart which arrived used and damaged. Of course I contacted them with pictures and they sent me out a replacement unit that arrived in satisfactory condition. So all in all I have had some bad luck with damaged units and replacement CNC however the customer support has been top notch. So if you do get a unit that is not up to par the Company will for sure make it right. So I will adjust my rating to 4 Stars and have to say that you can purchase with confidence that if you get a bad or damaged unit it will be replaced by the manufacturer. CNC router is together and I'm engraving. Keep in mind, no documentation on how to use a CNC router. For that you will have to go to the Facebook Group, search, read and experiment. Happy Engraving. EDIT: Bonus Content 2/14/2021 I have decided to rate this a 1 star. After I purchased the original CNC router I went to their company website and purchased their laser 159.00 USD. I just now go around to opening it up and installing it and guess what????? You guessed it, there was something missing. The power supply was missing. They sent the power cord which goes from the wall and to the power supply but no power supply. So I have a laser and no way to power it. I Do NOT recommend purchasing from this company. If you decide to sear TUMS you will need them.

M**L

Ik ben zeer tevreden met de 3018-PROVer V2. Het product was goed verpakt en de handleiding is gemakkelijk te begrijpen. De meegeleverde software is eenvoudig te installeren en gemakkelijk in het gebruik.

T**O

Il pacco è arrivato con qualche giorno di anticipo, che mi ha lasciato molto contento. Il prodotto è ben impacchettato, tutto è tenuto ben fermo da spessi strati di polistirolo. Unico difetto, nella mia scatola dei bulloni ne mancavano 2 M6, ho contattato il supporto SainSmart che me li ha recapitati in meno di 4 giorni. Il montaggio è semplificato rispetto ad altri prodotti ma richiede comunque un certo tempo, io ci ho messo circa 1 ora e mezza a completare tutto, e non ho messo il proteggi cavo in nylon perché mi riusciva male. Sono comunque molto soddisfatto perché le risorse fornite (sul sito sono presenti anche video tutorial) aiutano moltissimo e non c'è nulla da fare di veramente complicato. Una volta montata la CNC si presenta esteticamente molto bene, solida e con un colore azzurro che mi piace molto. Io la vorrei utilizzare principlamente per produrre circuiti stampati di progetti DIY, le prime prove mi hanno dato molta soddisfazione anche se ho ancora molto da imparare! Nel complesso la consiglio a chi ha tempo e voglia di imparare e studiare le varie tecniche/tecnologie per la fresatura con la CNC, lo sconsiglio a chi invece preferisce avere una soluzione "plug&play" che faccia subito tutto bene senza bisogno di metterci le mani. Allego qualche foto, scusate per la mia scrivania super disordinata :) ==== Automactic tranlsation in English ==== The package arrived a few days in advance, which left me very happy. The product is well packed, everything is held firmly by thick layers of foam. One defect, in my bolt box there were 2 M6 missing, I contacted SainSmart support which delivered them to me in less than 4 days. The assembly is simplified compared to other products but still requires some time, it took me about 1 and a half hours to complete everything, and I did not put the nylon cable protector because it was bad for me. I am however very satisfied because the resources provided (there are also video tutorials on the site) help a lot and there is nothing really complicated to do. Once mounted, the CNC looks aesthetically very well, solid and with a blue color that I really like. I would like to use it mainly to produce printed circuit boards for DIY projects, the first tests have given me a lot of satisfaction even though I still have a lot to learn! Overall, I recommend it to those who have the time and desire to learn and study the various techniques / technologies for CNC milling, I do not recommend it to those who prefer to have a "plug & play" solution that does everything right away without having to get their hands on it. I attach some photos, sorry for my super messy desk :)

P**A

21年4月購入。殆どプリアッセンブリされた状態で、部品もコンパクトにしっかりまとまった梱包となっている。メカ組立は容易で、電気配線もリミット他モジュール盤を指定の場所に取り付け配線するだけで、線の長さもピッタリになっておりつけられた線番タグ通り接続するのみ。ビギナーとして始めるにあたり馴染みやすい。まだcandleを使って多少の彫刻加工しかしておらず、まだそれほど使ってないですが、木材で簡単な加工がすぐに始められました。装置ガントリ部固定ナットのうち1個に不良がありましたが、サポート(日本語)により、追加のナットを送付してもらえました。欲を言うならば、Z軸ストロークがあと10~20mmあれば、使える工具幅も増えて使い勝手が向上するかと。同様に付属のプローブ厚みがもう5mmほど薄いほうがよいかもしれない。そしてアンチバックラッシュのバネは、もっと強いほうがいいと思います。 2022.6追記) 突然、Z軸動作不良でワークにエンドミルが喰い込み干渉のトラブル。調べた結果、z軸モーターケーブルの断線と判明。本件、製造&販売者のカスタマー・サービスへ連絡したら、素晴らしいサポート(日本語)対応で問題が解決。その他にも問合わせに丁寧な対応があり、購入後のフォローもなかなかしっかりしていると思います。

T**R

Ich habe mir diese Fräse vor allem für die Herstellung von PCB-Prototypen für meine Elektronik-Projekte zugelegt. Der Aufbau ist gut beschrieben und in ca. einer Stunde erledigt. Das Einfädeln der Kabel in die Kunststoff-Netze ist etwas fummelig, mit Geduld und einem Feuerzeug aber auch sauber machbar. Die Spindel ist relativ laut, läuft aber sauber zentriert und bisher sehr zuverlässig. Der Motor lässt sich auch günstig nachkaufen, falls etwas wäre. Der Bewegungsapparat hat viel Kraft und ist sehr präzise, die Steuerplatine ist sauber verarbeitet und bereits mit einer vorkonfigurierten GRBL-Version geflasht. Nach dem Aufbau kann es also direkt losgehen. Als Software wird eine ältere Version von Candle mitgeliefert, ich habe mir gleich die aktuelle Version von Github geladen. Damit lässt sich die Fräse sehr gut steuern, auch eine 3D-Vorschau und eine Heightmap kann erstellt werden. Ich habe mir noch eine zweite Krokodilklemme an das Kabel gemacht, um PCBs sauber ausmessen zu können. Für die Planung verwende ich meist Sprint Layout, als Präprozessor dann FlatCAM. Für das Isolation-Routing benutze ich ein 30° V-Bit mit 0.1mm Eintauch-Tiefe, dann einen 0.5mm Fräser für die Löcher und einen 2mm Fräser zum Herausschneiden. Bisher habe ich ca. 20 PCBs erstellt, die Genauigkeit ist auch für SMD absolut ausreichend. Fertige PCBs sprühe ich dann noch mit PCB-Lack ein, um sie vor Korrosion zu schützen. Auch Holz lässt sichgut bearbeiten, am besten geht natürlich weiches Material, aber bei entsprechend langsamerem Vorschub konnte ich auch mit Eiche gute Ergebnisse erzielen. Die Planung und das Erzeugen des Maschinen-Codes habe ich dafür komplett in Autodesk Fusion 360 durchgeführt, aber auch andere Software, die GRBL kompatiblen GCode erzeugt, kann benutzt werden. Die Reinigung ist aufgrund der schlanken Bauweise unproblematisch, und die mitgelieferten Verschraubungen halten das Werkstück sicher auf dem Tisch fixiert. Ich habe mir noch kleine Gummifüße gebastelt, damit die Schrauben beim Einspannen das Aluminium nicht verkratzen. Die maximale Breite des Werkstücks wird durch den Rahmen seitlich auf ca. 30cm beschränkt, nach vorne und hinten ist die Maschine offen und hat in der Tiefe einen Arbeitsbereich von ca. 18cm. Die maximale Höhe liegt bei etwa 5cm, höher kann die Spindel nicht angehoben werden. Für Namensschilder, kleine Formteile und natürlich PCBs ist das meist mehr als ausreichend. Für den Betrieb empfehle ich ein dauerhaft verbundenes Notebook, da man damit die beste Kontrolle und eine Vorschau hat. Mit dem mitgelieferten Controller kann man die Maschine zwar auch bewegen und GCode senden, durch das fehlende Feedback sind die Möglichkeiten dann aber eingeschränkt. Die Endstopps halten die Maschine bei Betätigung sofort an, dadurch wird verhindert dass man eine der Achsen zu weit bewegt und damit möglicherweise die Mechanik beschädigt. Auch ein Homing ist dadurch möglich, wobei man gerade bei dickeren Werkstücken aufpassen muss, dass der Fräser nicht an den Halterungen hängen bleibt. Auch der Not-Aus-Schalter ist ein praktisches Feature, weil man damit die Maschine vor einer Kollision oder bei einem abgerissenen Fräser sofort anhalten kann und Schäden vermeidet. Insgesamt eine sehr vielseitige kleine CNC-Fräse, auch gut für Einsteiger geeignet, für gute Ergebnisse muss man sich allerdings vertiefend mit CAM-Software auseinandersetzen und braucht in der Regel mehrere Versuche.

R**T

My First CNC machine. It seems very well built and went together easily. A few of the pre assembled parts had loose screws which were easy to fix. Still a learning curve with software choices etc. Probably can't say which software here. But the one that's commonly recommended works well. Learned a lot from on line forums in regard to setting up and first cuts. I had purchased a selection of bits and cutters at time of purchase. So no delays in trying things. I also upgraded to the 20000 RPM spindle from day one. Seems smooth and not too noisy, although first use was only at 12000 RPM. Looking forward to more projects.

TrustPilot

2 周前

2 周前