⚙️ Elevate your CNC game with precision that commands attention!

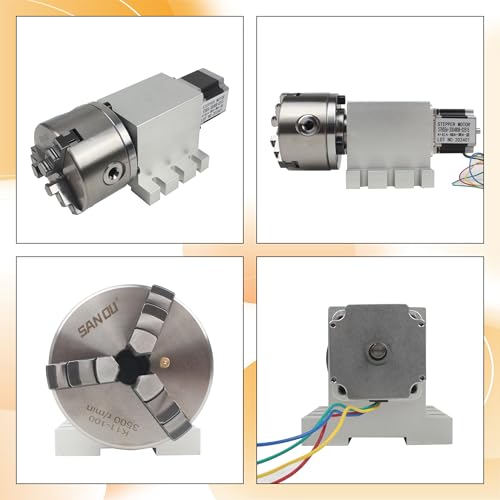

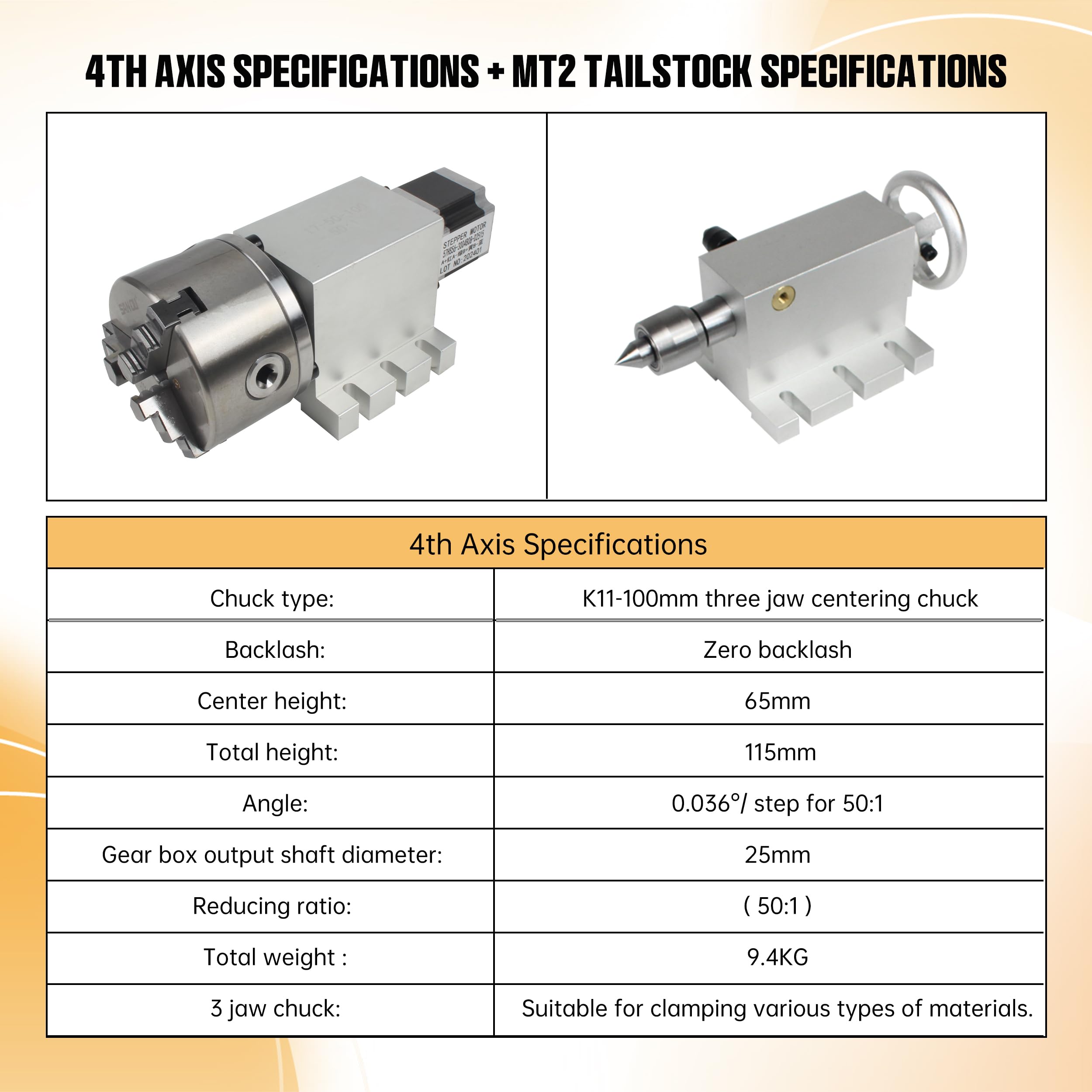

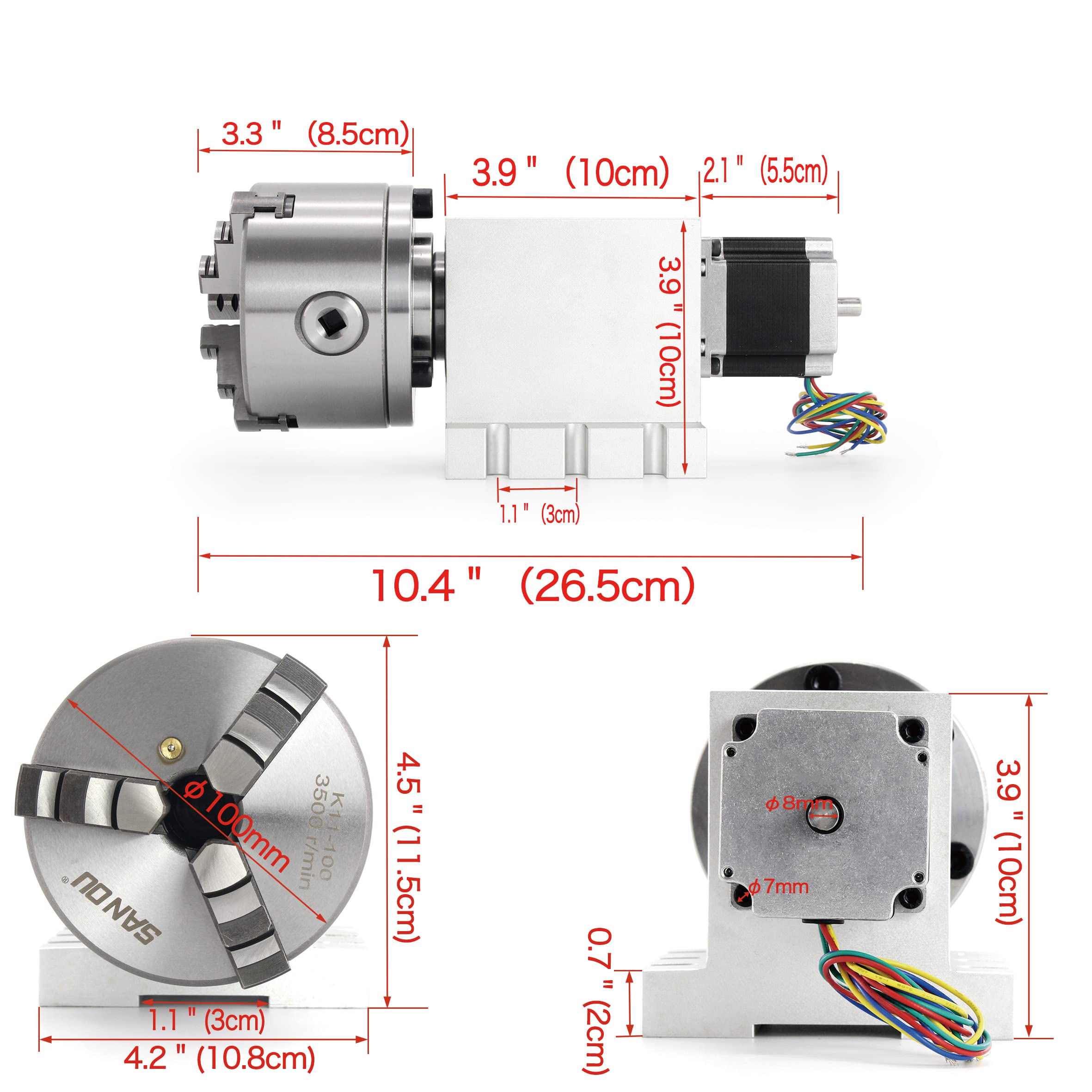

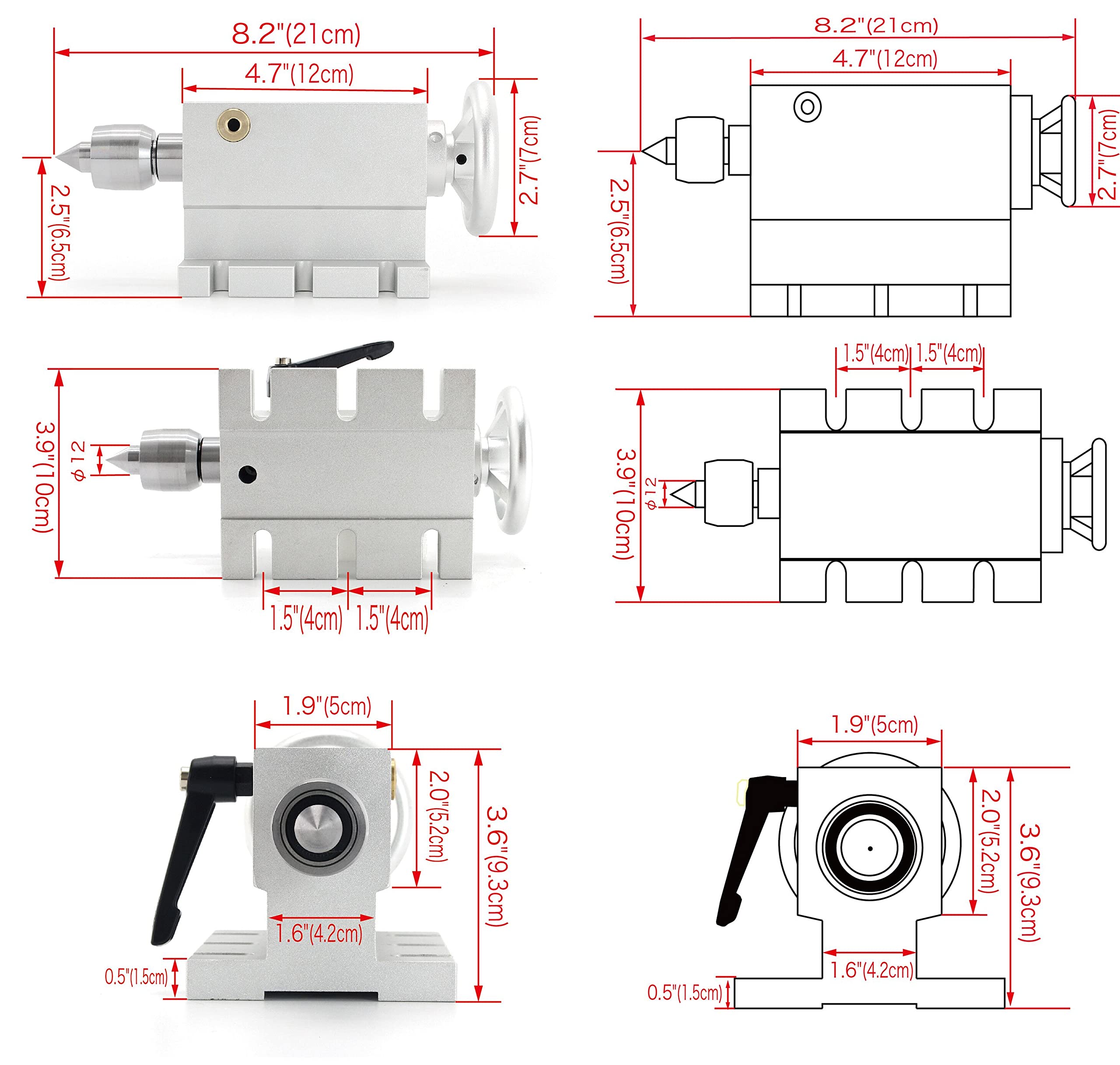

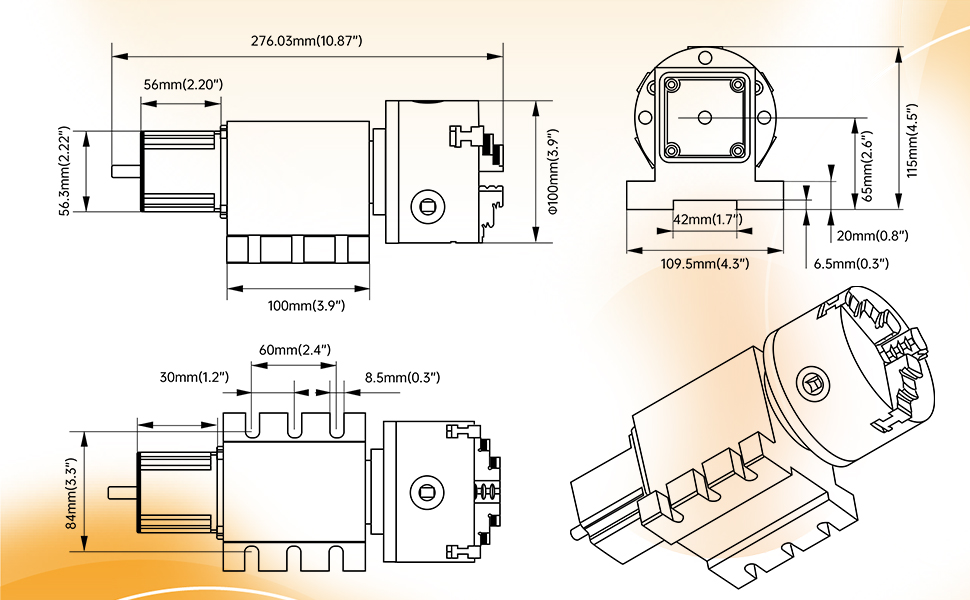

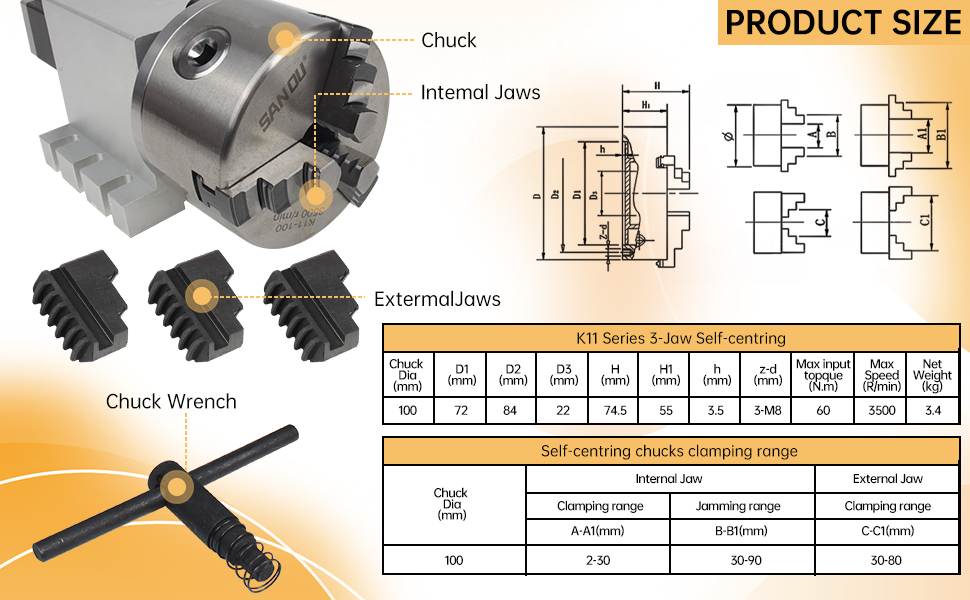

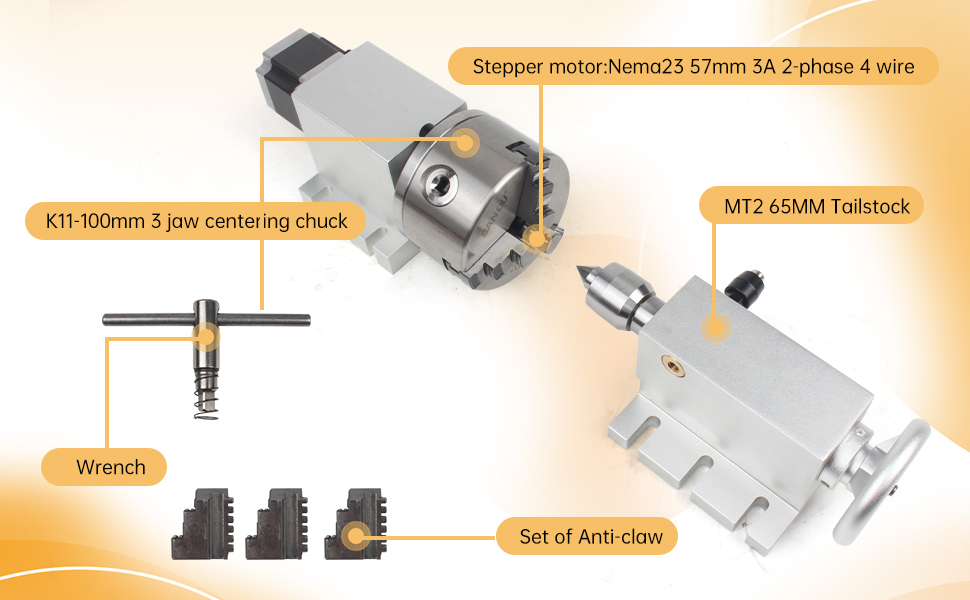

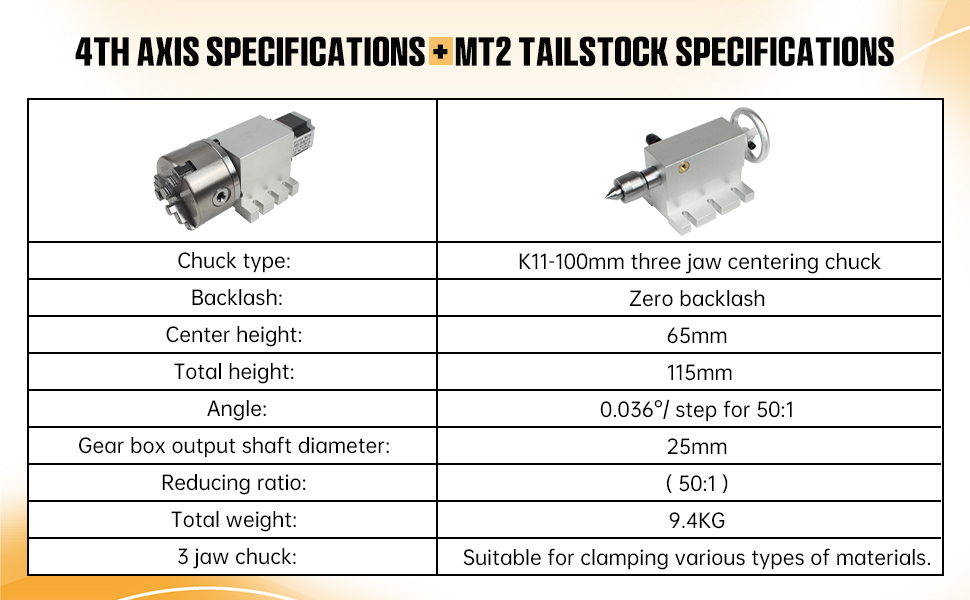

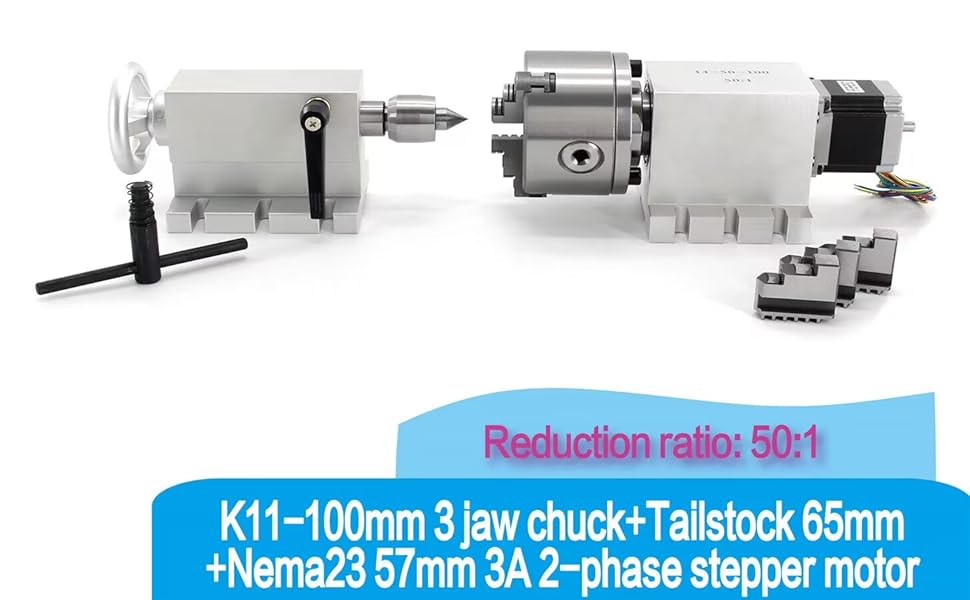

The CNCTOPBAOS 4th Axis Rotary Table features a high-precision 50:1 gapless harmonic gearbox, a robust 100mm K11-100 3-jaw self-centering chuck, and a 65mm height MT2 live center tailstock. Crafted from durable aluminum alloy with anti-rust coating, it offers smooth, backlash-free rotation with a fine 0.036° step angle. Designed for CNC routers and milling machines, it includes a NEMA23 stepper motor for easy integration, making it ideal for professional-grade engraving, milling, and light machining tasks.

| ASIN | B07B2SL9SD |

| Batteries Included? | No |

| Batteries Required? | No |

| Best Sellers Rank | #782,157 in Tools & Home Improvement ( See Top 100 in Tools & Home Improvement ) #212 in Power Milling Machines |

| Capacity | 63 Millimeters |

| Color | K11-100mm-50:1 |

| Customer Reviews | 3.9 3.9 out of 5 stars (13) |

| Cutting Diameter | 1E+2 Millimeters |

| Date First Available | May 12, 2017 |

| Handle Material | Aluminum |

| Included Components | 3 Jaw Chuck, Anti-claw, Nema23 Stepper Motor, Tailstock |

| Is Discontinued By Manufacturer | No |

| Item Package Quantity | 1 |

| Item Weight | 5.33 pounds |

| Item model number | K11-100mm 50:1 |

| Manufacturer | Changzhou Rattm Motor Co.,Ltd |

| Package Dimensions | 20 x 11.2 x 8 inches |

| Part Number | S23 |

| Size | 3 jaw 50:1 |

| Style | 3-jaw-50-1 |

| UPC | 785004502735 |

S**N

Good quality for the price, got it working on a Tormach/PassPilot

Excellent packaging and nice workmanship. The NEMA23 stepper at the end is open to the elements (coolant), and the flimsy cables are unprotected, both of which can either be accepted or fixed by adding a small enclosure that hides the stepper and cable nuts, plus an armored cable. Anyone with a use of a 4th axis can probably devise such an enclosure in an afternoon. the chuck is a standard low-cost CN-made 4" chuck. The electro-mechanical specs (stepper, gear ratio, and such) seemed to be the substantially the same as the 4" from TM, so I was hoping that, after configuring the DIP switches on TM's 4th axis integration kit appropriately for the TM 4" but lower current, and in PathPilot's UI selecting the 4" 4th axis option, it would work out of the box. It stepped just fine, but the angles were off by a bit. I had to adjust the SCALE value in the PathPilot 4th axis config file from 141.666666 (which, according to my math, would be appropriate for a 51:1 gear ratio) to 138.888888 (which is correct for a 1:50 gear ratio). If you don't know how to do that, google it in the LinuxCNC forums. If that's too much wizardy, then this product is probably not for you. The stepper is considerably less powerful than TM's NEMA34 stepper, but for my purpose--which can be best described as indexing rather than 4th axis continuous machining--it works just fine. I'm pretty sure there would be enough torque for light machining (maybe a 1/4" endmill and light cuts in AL). I haven't used the tailstock yet. For my first experiments, I put the whole thing into my 5" vise, which has just enough travel and was already properly aligned.

B**.

Unlucky with product, great Amazon support

Pro . The second unit I received worked very well. The machine has much more torque than I expected with zero detectable back-lash although this is based on fairly crude measurements.. I purchased the unit to work on 3/8 inch aluminum rod on a proper industrial milling machine and I feel that it would handle larger diameter steel rod if required. The chuck and steady seem quite good quality. The unit is easily controlled from a simple Arduino micro-processor using one of several freely available libraries and examples, I think I used a library called SpeedyStepper which allows quite elaborate movements. It will conveniently mount in a standard milling machine vise so there is no need to align it on the mill table if you have a good quality vise and you prefer to keep it in place. . Cons . If the first unit had operated properly I would have given 4 stars. Unfortunately it sounded during rotation as though a gear or bearing was grinding badly.. Amazon's return process worked beautifully and I had a replacement unit in a couple of days with plenty of time to return the original unit at no cost through a Kohl's store. The unit is not finish machined so its inherent precision is suspect but this will not matter for most applications. The supplied instructions are not great. In the end I discovered that putting the machine into operation was not very difficult but better instructions would have saved a lot of time. Do not forget that you will need a fairly capable driver to operate the unit.. This unit does not have a hole all the way through the body so you cannot work on long stock. About 5 inches would be maximum length. You cannot control this unit directly from a 4th axis output on an industrial grade milling machine. It is more correctly descried as an indexer rather than a 4th axis although some simple CNCs that use stepper motors rather than servos may be able to drive it directly. I am working on this with a CNC technician..

J**N

Pretty good little rotary.

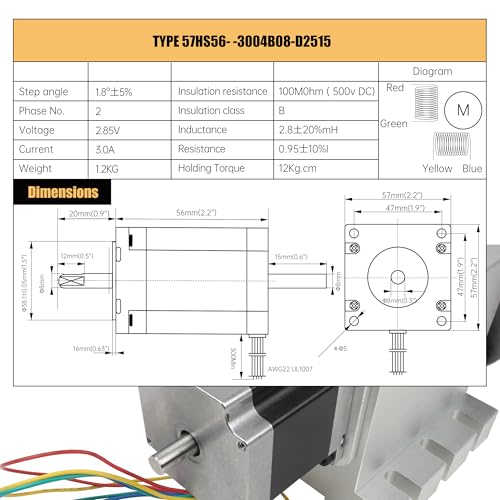

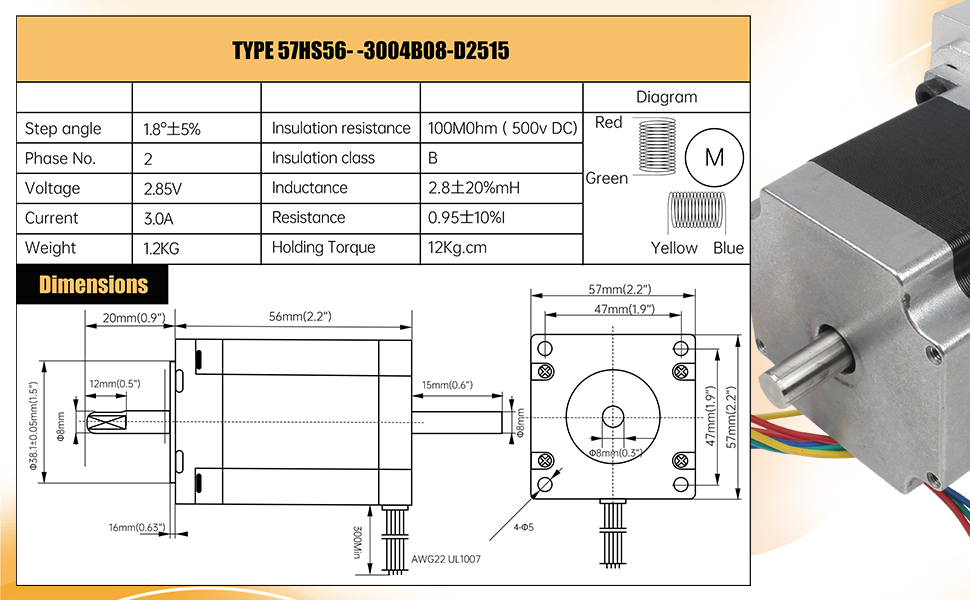

The first one I received had a ton of backlash and was really disappointing after reading the other reviews. While I was waiting for the replacement to arrive I decided to look inside and see what was wrong. When I removed the motor I found the two set screws on the motor shaft were loose so I tightened them, put it back together and measured this to only have 3 arc minutes of backlash. Happy with that I kept the original and sent the second one back unused. This didn't come with any directions so I had to go the internet for wiring the motor: A+ red, A- green, B+ yellow, B- blue. I have this running at 27500 degrees/minute which I think is pretty impressive considering the 50:1 reduction. To achieve that its running on 50 volts, at 2.84 peak amps. I really don't know if 50v is ok for this motor since there is no documentation with it, but that's what my system runs at so that's what its getting. My only other gripe is that this should really come with a 4 jaw chuck in stead of 3 since it will predominantly be used on routers.

M**N

OMG, what a deal

Works great. Smooth as silk with very little runout.

E**A

motor shaft is not as stated. what a waste of time. (edited couple months later)

I bought this so I can use my clearpath motors with it. It states that the motor shaft is 6.35mm or .25 inches. This is not so. THerefor Could not swap out the motors. Who knows what other stats is wrong on this thing. im editing this review. After having this little unit for a while. I can tell you it works pretty damn good. there was a little miscommunication about the shaft at the beginning. But I can let that slide. I had to bore it to the size of my motor shaft with my drill press. and its been working very well. Im thinking of buying another one.

J**P

Great value for the price

Not bad for what it is. Backlash in the gear housing could be better but the runout is OK and the tailstock is good

TrustPilot

2 个月前

1 个月前